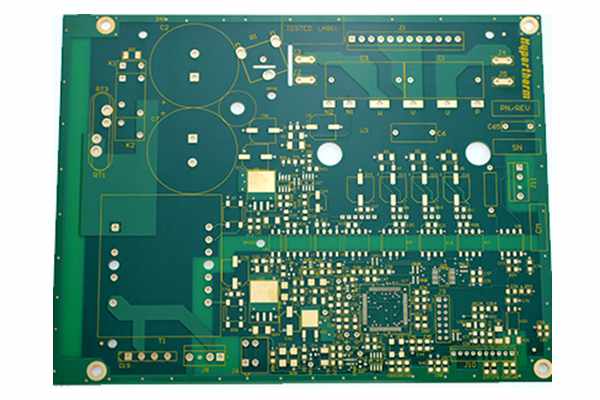

1. Kucheka

Tarisa iyo yakatarwa, modhi uye saizi yekucheka ye substrate board zvinoenderana nekugadzirwa kwechigadzirwa kana kucheka kudhirowa.Iyo longitude uye latitude kutungamira, kureba uye hupamhi dimension uye perpendicularity ye substrate board zviri mukati mechikamu chakatsanangurwa mudhirowa.

2. Silk screen process kudhinda

Kutanga, tarisa kana iyo skrini mesh, tension yescreen uye ukobvu hwefirimu zvinosangana nezvinodiwa.

Zvadaro, tarisa kutendeseka kwechimiro, uye hapana pinhole, notch kana yakasara yekunamatira firimu.Tarisa nepikicha yepakutanga bhodhi, uye saizi yekumisikidza inowirirana, uye upamhi hwemutsara, mutsara wemutsara, saizi yekubatanidza disk kana mavara emhando anowirirana.

3. Kucheneswa kwepamusoro

Iyo yakacheneswa nemakemikariPCBpamusoro pacho pachava pasina oxidation uye kusvibiswa, uye pachaoma mushure mekucheneswa.

4. Kudhindwa kwedunhu

Tarisa kuvimbika kwedhiyagiramu yedunhu, uye hapana dunhu rakavhurika, pinhole, notch kana pfupi pfupi.Tarisa neiyo yepakutanga bhodhi yemifananidzo, saizi yekumisikidza inowirirana, upamhi hwemutsara uye chinhambwe chemutsara zvinoenderana, uye kukanganisa kuri mukati meiyo inotenderwa renji.

5. Etching

Tarisa kuvimbika kwedhiyagiramu yedunhu, uye hapana dunhu rakavhurika, pinhole, notch kana pfupi pfupi.Tarisa neiyo foto yepakutanga bhodhi, uye hapana etching (mutsara wakanyanya kutetepa) kana kusakwana etching (mutsara wakanyanya kukora).

6. Resistance welding

Chekutanga, tarisa kutendeseka kweiyo solder resist graphics, uye hapana akarasika anodhinda, pinholes, notches, ink seepage, madziro akarembera, uye yakawandisa inki mavara.Inopindirana nehukuru hwekumisikidza kwemufananidzo wemutsara, uye kukanganisa kuri mukati meiyo inotenderwa.

Chechipiri, tarisa kurapa dhigirii rekudzivirira solder.Iyo solder resist layer pamusoro pemhangura conductor ichaedzwa nepenzura, uye kuomarara kwepenzura kuchapfuura 3H.

Chechitatu, tarisa simba rekubatanidza re solder rinopesana.Namira uye wokweva solder resist layer pane yemhangura girodhi pamusoro neadhesive tepi.Panofanira kunge pasina peeling solder kuramba patepi.

7. Positive and negative character marks

Tarisa uone kujeka kwemavara emavara, uye hapana kudhinda, mapinhole, notches kana inking, madziro akarembera, uye akawandisa inki dots.Zvinoenderana nesaizi yekumisikidza yemutsara wemifananidzo, kukanganisa kuri mukati meiyo inotenderwa renji, uye mucherechedzo wehunhu unogona kunyatso zivikanwa.

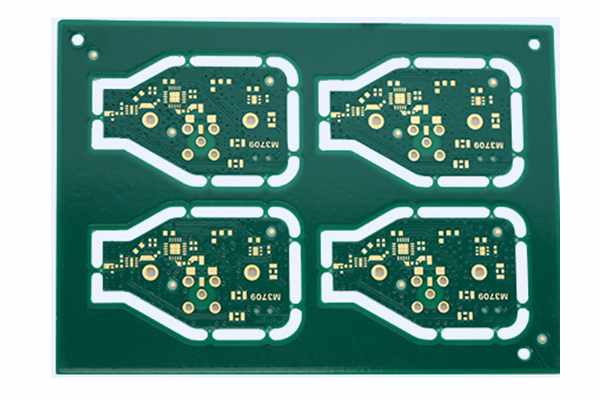

Isu tine chivimbo mukukupa iwe yakanakisa musanganiswa weturn-kiyi PCB musangano sevhisi, mhando, mutengo uye nguva yekuendesa mune yako Diki batch vhoriyamu PCB gungano odha uye Mid batch Vhoriyamu PCB gungano kurongeka.

Kana iwe uchitsvaga yakakodzera PCB gungano mugadziri, ndapota tumira ako BOM mafaera uye PCB mafaera kunesales@pcbfuture.com.Ese mafaera ako akavanzika zvakanyanya.Tichakutumira quote chaiyo ine nguva yekutungamira mumaawa makumi mana nemasere.

Nguva yekutumira: Zvita-01-2022