Nei tichifanira kubaya vias muPCB?

Kuti isangane nezvinodiwa nevatengi, iyo kuburikidza nemaburi mubhodhi redunhu inofanirwa kuvharirwa.Mushure mekuita kwakawanda, iyo yechinyakare aluminium plug hole process inoshandurwa, uye mambure machena anoshandiswa kupedzisa kuramba welding uye plug gomba redunhu bhodhi repamusoro, iro rinogona kuita kuti kugadzirwa kugadzikane uye mhando yakavimbika.

Via hole inoita basa rakakosha mukubatana kwemasekete.Nekuvandudzwa kweindasitiri yemagetsi, inosimudzirawo kuvandudzwa kwePCB, uye inoisa pamberi pepamusoro zvinodiwaPCB kugadzira uye kusanganateknolojia.Via hole plug tekinoroji yakatanga, uye zvinotevera zvinodikanwa zvinofanirwa kuzadzikiswa:

(1) Mhangura iri mugomba inokwana, uye solder mask inogona kuvharirwa kana kuti kwete;

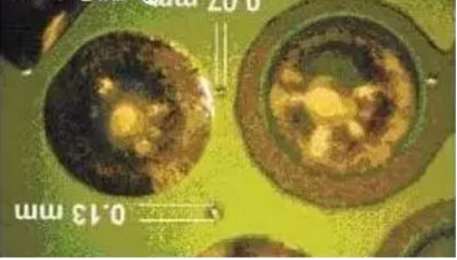

(2) Panofanira kuva nerata nemutobvu muburi repaburi, nehumwe hukobvu hunodiwa (4 microns), hapana solder inodzivisa ingi mugomba, inoita kuti marata avigwe mumakomba;

(3) Panofanira kunge paine solder resistance inki plug gomba muburi repaburi, risingaoneki, uye hapafanirwe kunge paine rin'i yerata, maranga uye flat.

Nekuvandudzwa kwezvigadzirwa zvemagetsi mugwara re "chiedza, chitete, chipfupi uye chidiki", PCB inokurawo yakanangana nepamusoro-soro uye kuoma kwakanyanya.Nokudaro, nhamba huru yeSMT neBGA PCBs yakaonekwa, uye vatengi vanoda kuvhara maburi kana vachiisa zvinhu, izvo zvinonyanya kuva nemabasa mashanu:

Nekuvandudzwa kwezvigadzirwa zvemagetsi mugwara re "chiedza, chitete, chipfupi uye chidiki", PCB inokurawo yakanangana nepamusoro-soro uye kuoma kwakanyanya.Nokudaro, nhamba huru yeSMT neBGA PCBs yakaonekwa, uye vatengi vanoda kuvhara maburi kana vachiisa zvinhu, izvo zvinonyanya kuva nemabasa mashanu:

(1) Kuti tidzivise kupfupika kwedunhu kunokonzerwa nerata inopinda nepakati pechinhu chepamusoro panguva yePCB pamusoro pemasaisai solder, kunyanya kana tikaisa gomba paBGA padhi, tinofanira kutanga tagadzira buri gomba uyezve goridhe plating kufambisa BGA soldering. .

(2) Dzivisa kuyerera kwasara mumaburi;

(3) Mushure mekukwira kwepamusoro uye chikamu chechikamu chefekitori yemagetsi, PCB inofanirwa kutora vacuum kuti iumbe kumanikidza kwakashata pamushini wekuyedza;

(4) Dzivirira solder yepasi kuti isayerera ichipinda mugomba, uye ichikonzera manyepo ekutengesa uye kukanganisa gomo;

(5) kudzivirira bhiza rekutengesa kubva pakubuda panguva yekushambadzira kwemafungu, uye kukonzera kupfupika.

Kuzadzikiswa kweplug hole tekinoroji ye kuburikidza negomba

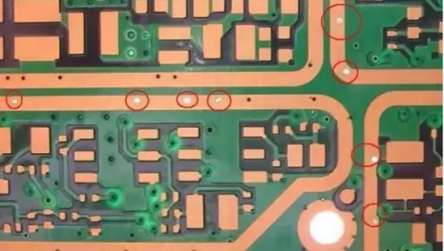

ForSMT PCB musanganobhodhi, kunyanya kuiswa kweBGA neIC, iyo via hole plug inofanira kunge yakati sandara, convex uye concave plus kana minus 1mil, uye hapafanirwe kunge paine tin dzvuku kumucheto kwegomba;kuitira kuti usangane nezvinodiwa nemutengi, iyo kuburikidza negomba plug hole process inogona kutsanangurwa seyakawanda, yakareba process inoyerera, yakaoma process control, pane kazhinji matambudziko akadai sekudonha kwemafuta panguva yekupisa kwemhepo kuyera uye girinhi mafuta solder kuramba bvunzo uye kuputika kwemafuta mushure. kuporesa.Zvinoenderana nemamiriro chaiwo ekugadzirwa, isu tinopfupisa akasiyana plug hole maitiro ePCB, uye anoita kumwe kuenzanisa uye kujekesa mukuita uye zvakanakira nekuipira:

Ongorora: iyo misimboti yekushanda yemhepo inopisa ndeye kushandisa mhepo inopisa kubvisa iyo yakawandisa solder pamusoro peyakadhindwa redunhu bhodhi uye mugomba, uye iyo yakasara solder yakavharwa zvakaenzana padhi, isina kuvharira solder mitsetse uye pamusoro pekurongedza nzvimbo. , inova imwe yenzira dzekurapa kwepamusoro kwebhodhi rakadhindwa redunhu.

1. Pikidza buri mushure mekupisa kwemhepo: plate surface resistance welding → HAL → plug hole → kupora.Iyo isiri-plugging process inogamuchirwa kugadzirwa.Mushure mekupisa kwemhepo kuyera, aluminium skrini kana inki yekuvhara skrini inoshandiswa kupedzisa kuburikidza negomba plug yenhare dzese dzinodiwa nevatengi.Plug hole inki inogona kunge iri photosensitive inki kana thermosetting inki, munyaya yekuve nechokwadi chemavara akafanana emufirimu wakanyorova, iyo plug hole inki ndiyo yakanakisisa kushandisa inki yakafanana nebhodhi.Iyi nzira inogona kuona kuti iyo kuburikidza negomba haidonhedze mafuta mushure mekupisa kwemhepo, asi zviri nyore kukonzera iyo plug hole inki kusvibisa ndiro pamusoro uye kusaenzana.Zviri nyore kuti vatengi vakonzerese kutengesa kwenhema panguva yekukwira (kunyanya BGA).Saka, vatengi vazhinji havabvumi nzira iyi.

2. Plug hole process isati yasvika mhepo inopisa: 2.1 plug gole nepepa realuminium, simbisa, kugaya ndiro, uye wozoendesa mifananidzo.Maitiro aya anoshandisa CNC yekuchera muchina kuburitsa kunze pepa realuminium rinoda kubatirwa gomba, kugadzira chidzitiro chendiro, plug gomba, simbisa iyo kuburikidza negomba plug gomba rakazara, plug hole ingi, thermosetting inki inogona kushandiswa zvakare.Hunhu hwayo hunofanirwa kunge hwakaoma hurefu, kudiki shrinkage shanduko yeresin, uye kunamatira kwakanaka nemadziro egomba.Iyo tekinoroji maitiro ndeaya anotevera: pretreatment → plug gomba → kukuya ndiro → kufambisa patani → etching → plate surface resistance welding.Iyi nzira inogona kuona kuti iyo kuburikidza negomba plug gomba yakatsetseka, uye kupisa kwemhepo kukwirisa hakuzove nematambudziko emhando sekuputika kwemafuta uye kudonha kweoiri pamucheto wegomba.Zvakadaro, kuita uku kunoda kukora kamwe chete kwemhangura kuita kuti ukobvu hwemhangura hwemadziro egomba huenderane nechiyero chemutengi.Nokudaro, ine zvakakosha zvemhangura yemhangura yeplate yose uye kushanda kweplate grinder, kuitira kuti ive nechokwadi chokuti resin pamusoro pemhangura inobviswa zvachose, uye mhangura yemhangura yakachena uye haina kusvibiswa.Mafekitari mazhinji ePCB haana nguva imwe chete yekukora mhangura, uye kushanda kwemidziyo hakugone kuzadzisa zvinodiwa, saka maitiro aya haawanzo shandiswa mumafekitori ePCB.

(The blank silk screen) (The stall point film mambure)

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. For more information, please email to service@pcbfuture.com.

Nguva yekutumira: Jul-01-2021