1. Finger Plating

In PCB proofing, masimbi asingawanzo akaputirwa pabhodhi kumucheto kongiri, bhodhi mupendero unobudikira kuonana kana munwe wegoridhe kuti upe yakaderera kuonana kuramba uye yakakwirira kupfeka kuramba, iyo inonzi munwe plating kana protruding munharaunda plating.Maitiro acho ndeaya:

1) bvisa coating uye bvisa tin kana tin lead coating pane yakabudikira kubata.

2) kugeza nemvura.

3) korobha neabrasive.

4) activation inopararira mu10% sulfuric acid.

5) nickel plating ukobvu pane yakabudikira kubata ndeye 4-5 μ m.

6) Kuchenesa kubvisa mineral water.

7) kuraswa kwegoridhe inonyorovesa mhinduro.

8) kuisa goridhe.

9) kuchenesa.

10) kuomesa.

2. Via plating

Kune nzira dzakawanda dzekumisa dhizaini ye electroplating pagomba remadziro e substrate drilling, inonzi gole wall activation mumaindasitiri maapplication.Iko kushandiswa kwekutengesa kushandiswa kwedunhu rayo rakadhindwa kunoda akawanda epakati ekuchengetedza matangi, imwe neimwe ine yayo yekutonga nekugadzirisa zvinodiwa.Via electroplating ndiyo inotevera inodiwa yekugadzira maitiro ekudhirowa kwekugadzira maitiro.Kana chibhorani chikadhirowa nepakati pefoiri yemhangura uye nepasi pasi, kupisa kunogadzirwa kunonamisa iyo insulating synthetic resin inoumba yakawanda ye substrate, uye iyo yakanyungudutswa resin uye mamwe marara ekuchera anoungana akatenderedza gomba uye anoputirwa pamadziro egomba achangobuda. mumhangura yemhangura, uye resin yakanyungudutswa ichasiyawo jira rinopisa rinopisa pamadziro egomba re substrate;Inoratidza kusanamatira kwakashata kune akawanda activator, izvo zvinoda kuvandudzwa kwemhando yetekinoroji yakafanana nekemikari chiito chekubvisa tsvina uye corrosion kumashure.

Imwe nzira yakakodzera yePCB proofing ndeye kushandisa yakanyatso gadzirwa yakaderera viscosity inki, ine yakasimba adhesion uye inogona kusungirirwa zviri nyore kune akawanda anopisa akakwenenzverwa madziro emadziro, nokudaro kubvisa nhanho yetchback.

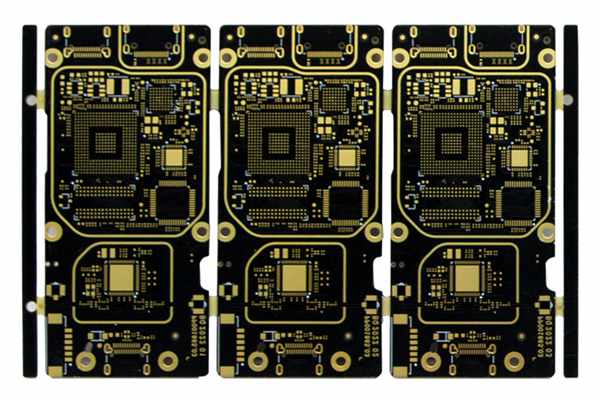

3.Roller yakabatana yakasarudzika plating

Mapini uye mapini ekubatanidza ezvikamu zvemagetsi, senge majoini, maseketi akasanganiswa, transistors uye anochinjika akadhindwa maseketi, anosarudzwa akapfava kuti awane yakanaka yekubata kuramba uye kushora kuramba.Iyi nzira ye electroplating inogona kuve yemanyorero kana otomatiki.Zvinodhura zvakanyanya kumisa kusarudzwa kwepini yega yega, saka batch welding inofanira kushandiswa.Mukusarudza nzira yekuisa, tanga wapfekedza firimu re inhibitor pane zvikamu zvesimbi yemhangura foil isingade electroplating, uye ingomira electroplating pane yakasarudzwa yemhangura foil.

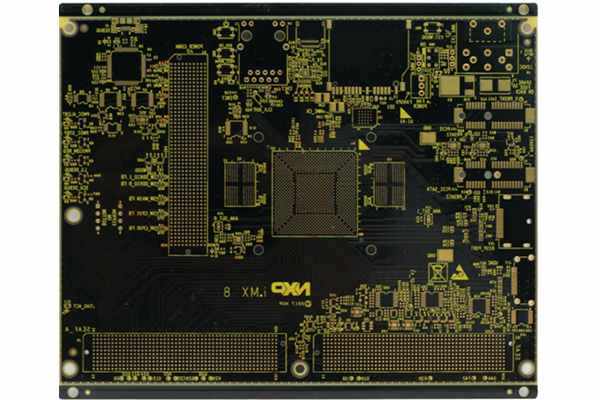

4.Brush plating

Brush plating ndeye electrostacking tekinoroji, iyo inongomisa electroplating munzvimbo ine shoma uye haina mhedzisiro pane zvimwe zvikamu.Kazhinji, simbi dzisina kujairika dzakaputirwa pazvikamu zvakasarudzwa zvebhodhi redunhu rakadhindwa, senge nzvimbo dzakadai sebhodhi edge connectors.Brush plating inonyanya kushandiswa mukatielectronic assembly workshopskugadzirisa tsvina yedunhu mapuranga.

PCBFuture yakavaka mukurumbira wedu wakanaka mune yakazara turnkey PCB musangano sevhisi indasitiri yeiyo prototype PCB gungano uye yakaderera vhoriyamu, yepakati vhoriyamu PCB gungano.Izvo vatengi vedu vanofanirwa kuita kutumira iyo PCB dhizaini mafaera uye zvinodiwa kwatiri, uye isu tinokwanisa kutarisira basa rose.Isu tinokwanisa zvizere kupa asingarondeke turnkey PCB masevhisi asi kuchengetedza mutengo wakazara mukati mebhajeti rako.

Kana iwe uchitsvaga yakakodzera Turnkey PCB gungano mugadziri, ndapota tumira yako BOM mafaera uye PCB mafaera kune sales@pcbfuture.com.Ese mafaera ako akavanzika zvakanyanya.Tichakutumira quote chaiyo ine nguva yekutungamira mumaawa makumi mana nemasere.

Nguva yekutumira: Zvita-13-2022