16 mhandoyezvakajairika PCBsolderingkuremara

Mukusangana kwePCB, kwakasiyana kwakasiyana kunowanzoitika, senge manyepo soldering, overheating, bridging uye zvichingodaro.Pazasi PCBfuture inotsanangura zvakajairikaPCB musanganokukanganisa kana kutengeswa maPCB uye maitiro ekuzvidzivirira.

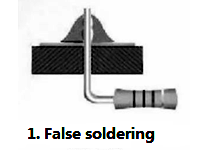

1. Kutengesa kwenhema

Mamiriro ekuonekwa: pane muganho mutema uri pachena pakati pe solder nechikamu lead, kana foil yemhangura, uye solder iri concave kumuganhu.

Kukuvadza: kusashanda nemazvo.

Chikonzero: kutungamirira kwezvikamu hakuna kucheneswa, tini haina kuputirwa kana tini yakasvibiswa.Iyo yakadhindwa yedunhu bhodhi haina kucheneswa, uye mhando yekupfapfaidza flux haina kunaka.

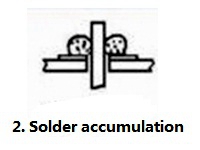

2. Solder kuunganidza

Mamiriro ekuonekwa: iyo solder yekubatanidza chimiro chakasununguka, chichena uye chisina kupenya.

Kukuvadza: kusakwana kwesimba remagetsi kunogona kukonzera welding yenhema.

Chikonzero: murombo solder quality.Welding tembiricha haina kukwana.Kana iyo solder isina kusimba, chikamu chinotungamira chakasununguka.

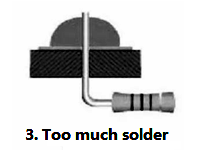

3. Kunyanya solder

Chitarisiko chinotaridzika: iyo solder pamusoro iri convex.

Kukuvadza: solder inoraswa uye kukanganisa kunogona kusaonekwa nyore.

Chikonzero: kushanda kusina kunaka panguva yekutengesa.

4. Kunyanya solder

Mamiriro ekuonekwa: iyo welding nzvimbo iri pasi pe80% yepadhi, uye solder haina kuumba yakatsetseka shanduko yepamusoro.

Kukuvadza: kusakwana kwesimba remagetsi.

Chikonzero: solder mobility yakashata kana nguva isati yakwana solder kubvisa.Kuyerera kusina kukwana.Nguva yewelding ipfupi.

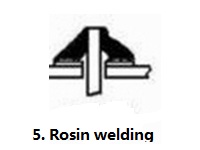

5. Rosin welding

Mamiriro ekuonekwa: kune rosin slag mune weld.

Kukuvadza: kusakwana kwesimba, kusafambisa zvakanaka, dzimwe nguva kudzima nekudzima.

Chikonzero: kune akawanda akawandisa welding michina kana welder kutadza.Kusakwana welding nguva uye kudziyisa.Iyo yepamusoro oxide firimu haina kubviswa.

6. Kupisa

Mamiriro ekuonekwa: white solder joint, hapana metallic luster, rough surface.

Kukuvadza: padhi iri nyore kubvisa uye simba rinoderedzwa.

Chikonzero: simba resimbi yesimbi yakakura kwazvo, uye nguva yekupisa yakareba.

7. Cold welding

Mamiriro ekuonekwa: Iyo yepamusoro ine granular, uye dzimwe nguva panogona kuve nekutsemuka.

Kukuvadza: Simba rakaderera uye kusaita zvakanaka.

Chikonzero: solder inozununguswa isati yasimba.

8. Kupinda kusina kunaka

Mamiriro ekuonekwa: iyo interface pakati pe solder uye weldment yakakura kwazvo uye haina kutsvedza.

Kukuvadza: simba rakaderera, hapana kuwana kana nguva-pa uye kure.

Chikonzero: iyo weldment haina kucheneswa.Flux haina kukwana kana kuti yakashata mhando.Iyo weldment haina kupisa zvakakwana.

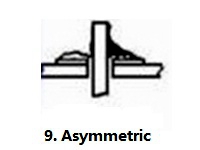

9. Asymmetric

Mamiriro ekuonekwa: solder haiyerere pamusoro pedhi.

Kukuvadza: Simba risina kukwana.

Chikonzero: solder ine murombo fluidity.Kusakwana flux kana hurombo husina kunaka.Kusakwana kupisa.

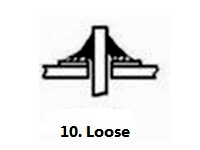

10. Yakasununguka

Maitiro ekuonekwa: Waya kana chikamu chinotungamira chinogona kutamiswa.

Kukuvadza: kushomeka kana kusaitisa.

Chikonzero: solder isati yasimba, waya inotungamira inofamba ichikonzera voids.Iyo inotungamira haina kugadziriswa zvakanaka.

11. Cusp

Chitarisiko maitiro: unopinza.

Kukuvadza: kutaridzika zvakanaka, nyore kukonzera bhiriji

Chikonzero: yakawandisa flux uye yakanyanyisa kupisa nguva.Iyo yekusiya kona yesimbi yekusimbisa haina kunaka.

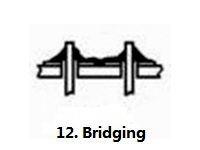

12. Kuvharisana

Maitiro ekuonekwa: waya dziri pedyo dzakabatanidzwa.

Kukuvadza: Electrical short circuit.

Chikonzero: yakawandisa solder.angle isina kukodzera yekudzokororwa kwesimbi ye soldering.

13. Pinho

Mamiriro ekuonekwa: kuongorora kwekuona kana mashoma-simba amplifiers anogona kuona maburi.

Kukuvadza: simba risina kukwana, solder joint iri nyore kuodza.

Chikonzero: mukaha uripo pakati pemutobvu negomba repadhi wakakurisa.

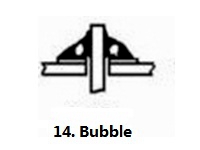

14. Mapupu

Mamiriro ekuonekwa: kune moto unofema solder bulge pamudzi wekutungamirira, uye gomba rakavanzwa mukati.

Kukuvadza: kuitisa kwenguva pfupi, asi zviri nyore kukonzera kutadza kuita kwenguva yakareba.

Chikonzero: mukaha pakati pekutungamira uye welding disc gomba rakakura.Kupinza mutobvu kusina kunaka.Nguva yewelding yekaviri-sided plugging kuburikidza nemakomba yakareba, uye mhepo mumakomba inowedzera.

15. Copper foil yakamonyoroka

Mamiriro ekuonekwa: iyo foil yemhangura inobviswa kubva pabhodhi rakadhindwa.

Kukuvadza: PCB yakakuvadzwa.

Chikonzero: nguva yewelding yakarebesa uye tembiricha yakanyanya.

16. Kukururwa

Maitiro ekuonekwa: majoini ekutengesa anobvisa kubva papepa remhangura (kwete foil yemhangura uye PCB).

Kukuvadza: Vhura dunhu.

Chikonzero: yakashata simbi yakanamirwa padhi.

PCBFuture inopa ese anosanganisirwa PCB musangano masevhisi, anosanganisira PCB kugadzira, chikamu chekutsvaga uye PCB gungano.YeduTurnkey PCB sevhisiinobvisa kudiwa kwako kubata vatengesi vakawanda pamusoro pemafuremu akawanda enguva, zvichikonzera kuwedzera kushanda nesimba uye kuita mutengo.Sekambani inofambiswa nemhando, isu tinopindura zvizere kune zvinodiwa nevatengi, uye tinogona kupa panguva uye yakasarudzika masevhisi ayo makambani makuru asingagoni kutevedzera.Isu tinogona kukubatsira kuti udzivise PCB solder kukanganisa mune zvigadzirwa zvako.

Nguva yekutumira: Nov-06-2021